PPS injection molding services

What is PPS?

PPS (Polyphenylene Sulfide) resin is classified as a super engineering plastic, featuring a high melting point of approximately 280°C, excellent chemical resistance, and self-extinguishing properties. However, PPS resin is also known for its tendency to generate burrs and gas during the molding process.

To accommodate PPS resin molding, our company has equipped our injection molding machines (ranging from 15 tons to 100 tons) with high corrosion- and wear-resistant screws and cylinders. We also have extensive experience in using PPS resins reinforced with GF30–40% from various resin manufacturers.

During molding, we pay close attention to the position and depth of gas vents to suppress burr formation and prevent short shots caused by gas accumulation. In particular, crystalline resins with reinforcing materials exhibit high anisotropy (due to the glass fiber content), making it essential to have expertise in keeping gear components within JIGM standards.

Similarly, for complex-shaped parts, anisotropy can make it challenging to maintain dimensions within tolerance limits. Additionally, since PPS resin tends to generate gas easily, mold deposits (MD) can accumulate in gas vents during mass production, leading to defects such as surface roughness (due to glass fiber protrusion) or dimensional inaccuracies. Therefore, proper maintenance frequency management is crucial.

Production Capacity

Production Capacity

Monthly Capacity:

up to 500,000 pcs

Equipment

Injection Molding Machine

α-S15iA: 5 units

α-S30iA: 11 units

α-S50iA: 11 units

α-S100iA: 1 unit

FAQ

About Transactions

- Can we visit the factory?

- Where are your production facilities located?

- Can you handle production transfers?

- Do you have Japanese staff members?

- We are a company outside of Vietnam. Is it possible to have an online meeting?

- Can you support local companies in Vietnam as well?

- Is it possible to deliver outside of Vietnam?

- Which currencies do you support for transactions?

- What languages do you support?

About Molding

- What product sizes can you operate?

- Do you support drawings with inch specifications?

- Can you support assembly?

- Can you support prototyping?

- What materials can you operate?

- Is it possible to injection mold lenses?

- What post-molding processes can you operate?

- Can you operate product coloring?

- Do you handle hot runners?

- How long does it take until the first trial?

About Quality Control

About JURARON Group

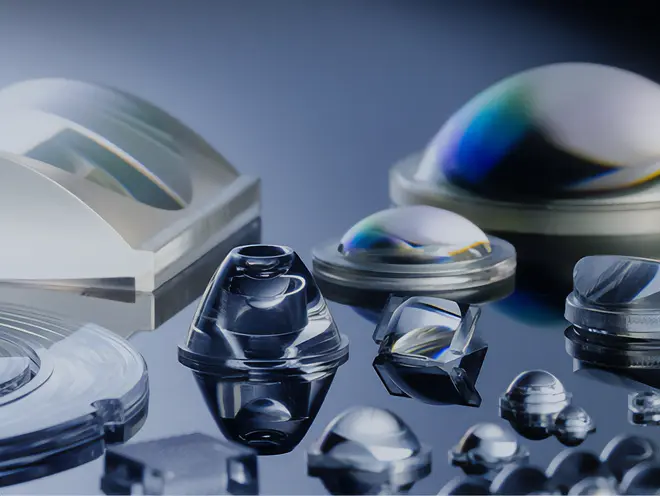

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.