POM injection molding services

What is POM?

POM, chemically known as polyacetal copolymer, is a highly crystalline, thermoplastic engineering plastic. Our company frequently utilizes POM resin in various gear-related products and has experience molding POM resins containing additives such as carbon powder and calcium carbonate powder.

The standard molding conditions for POM include a resin temperature of 190–210°C, a mold temperature of 60–80°C, and pre-drying at 80–90°C for 3 to 4 hours.

If POM remains stagnant, it generates formaldehyde gas, which has a very strong pungent odor. To ensure safety, our company avoids allowing formaldehyde gas to stagnate for more than 10 minutes. When stopping the molding process, we purge the system and lower the cylinder temperature before shutting down. As a company standards , we either purge or reduce the cylinder temperature before stopping operations. Additionally, for production efficiency, gas vents are always installed at the final filling positions, and regular maintenance is performed, similar to other general resins. For products with significant wall thickness variations or those requiring complex slide mechanisms, CAE analysis is conducted to determine the optimal gate and gas vent positions before proceeding with mold production.

Production Capacity

Production Capacity

Monthly Capacity:

up to 10,000,000 pcs

Equipment

Injection molding machines

α-S15iA: 5 units

α-S30iA: 11 units

α-S50iA: 11 units

α-S100iA: 1 unit

FAQ

About Transactions

- Can we visit the factory?

- Where are your production facilities located?

- Can you handle production transfers?

- Do you have Japanese staff members?

- We are a company outside of Vietnam. Is it possible to have an online meeting?

- Can you support local companies in Vietnam as well?

- Is it possible to deliver outside of Vietnam?

- Which currencies do you support for transactions?

- What languages do you support?

About Molding

- What product sizes can you operate?

- Do you support drawings with inch specifications?

- Can you support assembly?

- Can you support prototyping?

- What materials can you operate?

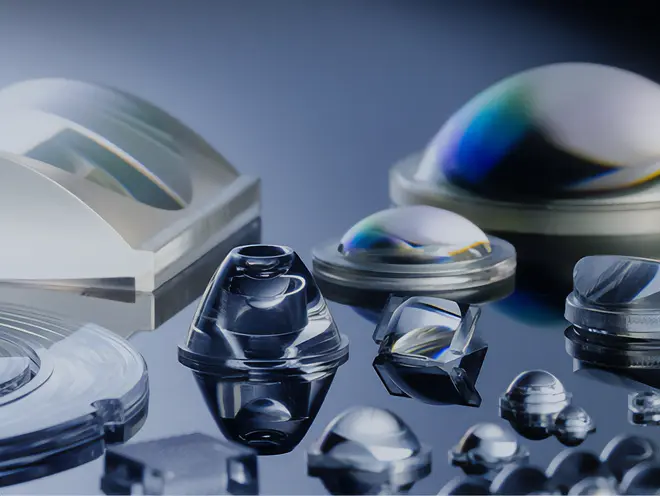

- Is it possible to injection mold lenses?

- What post-molding processes can you operate?

- Can you operate product coloring?

- Do you handle hot runners?

- How long does it take until the first trial?

About Quality Control

About JURARON Group

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.