Blogs

2025.06.09

Features of High-Temperature Injection Molding Machines

Features of High-Temperature Injection Molding Machines

Compared to standard injection molding machines, high-temperature models are capable of melting and molding resins at significantly higher temperatures – over 400°C. The output of the band heaters used to heat the cylinder and nozzle is also specially configured for high-temperature applications. The cylinder is made of KH material, a highly heat-resistant alloy with excellent corrosion and wear resistance. The screw is also made from a highly heat-resistant material with excellent corrosion and wear resistance. These specifications enable the molding of specialized engineering plastics with excellent heat and wear resistance.

Mold Management

To ensure consistent product quality, precise control of mold temperature is essential. For mold temperature control, cartridge heaters are used as the heating medium to maintain consistent mold temperatures. The number, wattage, and placement of cartridge heaters must be carefully considered during mold design and manufacturing. Taking into account the power consumption of both band heaters and cartridge heaters, the main power capacity of the injection molding machine has been increased compared to standard models. Molds used for high-temperature injection molding have different characteristics and requirements compared to standard molds. Materials with a low coefficient of thermal expansion are selected to ensure dimensional stability of molded parts even under high temperatures. In addition, we select mold materials that are best suited to each type of resin we work with.

Specific Types of High-Temperature Materials

Examples of heat-resistant resins that demonstrate stable performance under high-temperature conditions include the following materials, which we have actual experience using in our operations.

Polyphenylene Sulfide (PPS):

PPS has exceptionally high heat resistance, with a continuous use temperature of 220~ 240°C – significantly higher than that of general-purpose plastics. It is suitable for high-temperature components and electronic device parts, as it resists deformation and loss of strength even under high-temperature conditions.

Polyether Ether Ketone (PEEK):

PEEK exhibits excellent heat resistance, chemical resistance, and wear resistance. Thanks to these outstanding properties, it is widely used in various fields such as medical devices, the automotive industry and other fields like aerospace applications.

Fluoropolymer (ETFE):

ETFE is a resin with an excellent combination of properties, including heat resistance, chemical resistance, and non-stick characteristics. In OA (office automation) components, it is used in parts such as paper feed rollers, taking advantage of its low friction properties.

Conclusion

At our company, we upgrade the three-piece screw tip set of the injection molding machine (screw head, check ring, and spacer) to a high-temperature specification, enabling it to handle glass fiber-reinforced materials that impart properties such as high strength, rigidity, and heat resistance to plastics. However, since the shape of the filler can affect the cylinder, screw, and the three-piece tip set differently, it may be difficult to determine compatibility based solely on the glass fiber content. Please consult us regarding the materials you intend to use.

About JURARON Group

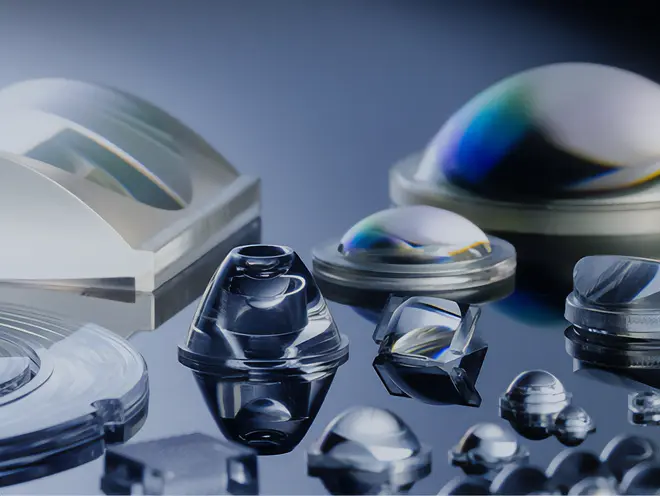

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.