Blogs

2025.09.24

Important Tips for Injection Molding Small Precision Parts

Injection molding of small precision parts may seem similar to general injection molding, but there are specific considerations unique to this process. This article introduces important tips when molding small precision components.

What is Injection Molding?

Injection molding is a forming method in which plastic or similar materials are heated until molten, injected into a mold under high pressure, and then cooled and solidified to form a product with the desired shape.

The term “injection” comes from the way the material is delivered into the mold, similar to how liquid is injected with a syringe.

Key Considerations in Injection Molding of Small Precision Components

In the injection molding of small precision parts, the product size is so small that the shot volume becomes extremely low. This means that the actual amount of resin injected is significantly smaller than the injection capacity of the molding machine.

While general molding allows for a certain level of adjustment through machine settings, such adjustments are very limited when it comes to small precision components.

Due to this characteristic, the mold structure becomes far more critical than the machine settings. The more precise and well-designed the mold is, the more stable and efficient the mass production process will be. In other words, mold design and fabrication are the most crucial elements in the injection molding of small precision parts.

If this aspect is overlooked, unexpected defects in product shape or instability during production may occur, even if the mold itself has been completed.

At Juraron, we address these challenges by handling both product design and mold structure design in-house. We also work closely with our mold manufacturing partners to ensure the highest level of precision and product quality.

Experts in Small Precision Injection Molding

What do you think?

In this article, we’ve outlined the key considerations in injection molding of small precision parts, along with Juraron’s approach to mold design and manufacturing.

If you are facing challenges with small part injection molding, please feel free to consult with Juraron.

With our years of experience and technical expertise, we are ready to support your project and help solve your manufacturing challenges.

About JURARON Group

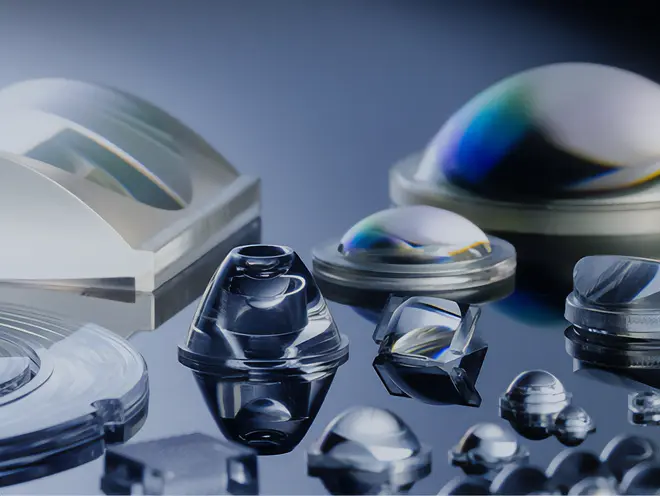

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.