Blogs

2025.10.30

Precautions in Pulley injection molding

Pulleys are precision components in injection molding, requiring careful consideration of material selection, mold design, and molding conditions. In this article, we highlight important precautions when injection molding plastic pulleys.

Precision Requirements in Pulley Injection Molding

Pulleys are used in combination with belts or rollers, so even slight deviations in rotational or dimensional accuracy can lead to operational issues.

To prevent this, the outer diameter, groove width, and shaft hole dimensions must be kept within specified tolerances, while minimizing deformation caused by resin shrinkage.

Key Considerations in Material Selection

Material selection for pulleys is a critical factor affecting product durability and cost.

Engineering plastics are commonly used, with POM and PA being the most frequently chosen materials.

POM offers excellent wear resistance and dimensional stability, making it ideal for small pulleys in printers and multifunction devices.

PA is often selected when heat resistance and mechanical strength are prioritized.

For pulleys requiring high precision, materials like PC with high strength and low shrinkage rates are also used.

Key Considerations in Mold Design and Manufacturing

Achieving high precision in pulley injection molding requires careful consideration during the mold design phase. Since pulleys are rotating components, ensuring roundness and concentricity is crucial. Therefore, it is necessary to improve cavity machining accuracy and apply surface treatments to prevent wear.

Additionally, gate location and runner design must be carefully planned to ensure uniform resin flow. Improper gate placement can cause uneven filling, leading to deformation or sink marks.

Particularly at the pulley’s outer circumference, differences in cooling rates can cause warping, so uniform cooling channel layout is essential.

For multi-cavity molds producing large quantities, flow analysis and gate balance considerations are required.

Precautions in Injection Molding

In the injection molding process, controlling temperature, pressure, and time greatly affects product quality. Especially for pulleys, which require high precision, even slight changes in molding conditions can result in dimensional defects.

Excessive temperature during injection can cause resin degradation, reducing strength and causing demolding issues. Conversely, low temperature or low resin viscosity can lead to short shots and weakened weld lines.

Injection pressure and holding time are also critical; improper settings can cause flash or deformation, so molding conditions must be optimized.

Leave pulley injection molding to us!

What do you think? In this article, we introduced key precautions for pulley injection molding as well as Juraron Industries’ approach.

If you are facing challenges in precision molding of small parts, please consider consulting Juraron Industries. With years of experience and technical expertise, we are here to support you in solving your problems

About JURARON Group

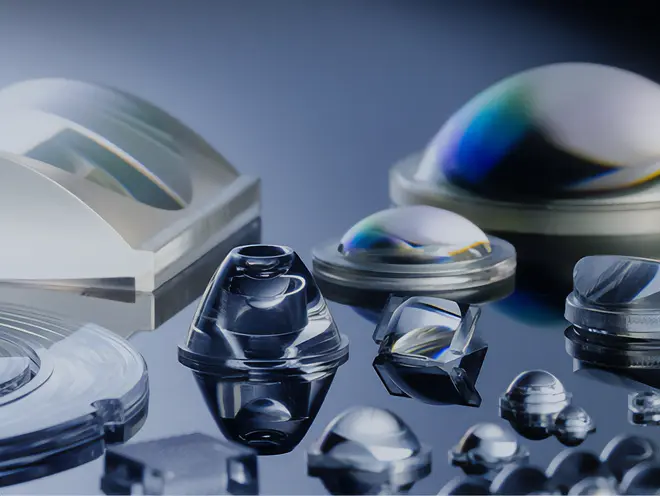

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.