Blogs

2025.11.30

Points to Note in Injection Molding of Gears

Injection molding is an excellent technology that enables the efficient mass production of high-precision components. However, it is also necessary to understand the specific considerations associated with this process. This article explains the key molding factors that influence the performance of gears.

Accuracy Requirements in Injection Molding of Gears

Gears are important mechanical components that transmit power and require high precision. The accuracy of molded gears is evaluated based on various factors such as tooth profile, pitch, and tooth thickness. Insufficient precision can lead to poor meshing between gears, increased noise and vibration, reduced transmission efficiency, and even early wear or failure. Particularly in modern products that are increasingly compact and lightweight, even slight dimensional errors are unacceptable. Therefore, strict quality control throughout the injection molding process is essential.

Points to Consider in Material Selection

In gear injection molding, selecting the optimal material is the first critical step that determines product quality. The performance required for gears varies greatly depending on the operating environment.

For example, when high strength and wear resistance are required, polyacetal (POM) or polyamide (PA) are commonly used.

On the other hand, when heat resistance and dimensional stability are important, super engineering plastics such as PPS (polyphenylene sulfide) or PEEK (polyether ether ketone) are suitable.

Additionally, in harsh operating environments, adding glass fiber or carbon fiber can further enhance strength and rigidity. However, additives affect molding shrinkage, so it is necessary to select materials with a full understanding of these properties.

Points to Consider in Mold Design and Manufacturing

The accuracy of gears is determined by mold design and manufacturing. In particular, the precision of the cavity that transfers the tooth profile directly affects the final product quality. In mold design, it is extremely important to accurately predict material shrinkage during molding and set dimensions accordingly.

Because gears have complex shapes, injection pressure may not be applied uniformly, leading to variations in local shrinkage. To avoid this, the gate position and number, as well as runner thickness, should be optimized to ensure the resin flows smoothly throughout the cavity.

Additionally, to prevent deformation when removing the molded part from the mold, it is important to provide appropriate draft angles and carefully consider the placement of ejector pins. Mold manufacturing requires high-precision machining equipment and skilled technicians.

Points to Note During Injection Molding

Once the mold is completed, optimizing the injection molding machine settings helps minimize defects. Injection speed affects how the resin fills the cavity and directly influences product quality. If the speed is too high, burn marks or flash may occur; if it is too low, short shots or weld lines can form.

Injection pressure is an important factor for filling the cavity and compensating for shrinkage. Insufficient pressure can cause sink marks or short shots, while excessive pressure may lead to mold opening or flash.

Resin temperature and mold temperature are also critical parameters. If the resin temperature is too high, thermal degradation may occur; if it is too low, flowability deteriorates. Mold temperature regulates the cooling speed of the molded part and is essential for controlling shrinkage and warpage.

These parameters should not be adjusted independently, as they influence one another. Therefore, finding optimal molding conditions requires balancing them comprehensively.

Quality Control After Molding

Even after gear molding is completed, proper management is essential to maintain product quality. During the cooling process, the molded parts may shrink and undergo slight deformation. Therefore, to supply products with stable quality, it is important to continuously monitor and maintain consistent molding conditions.

In addition, the product dimensions must be measured regularly to ensure that they meet the design specifications. In particular, the accuracy of the tooth profile must be strictly inspected using dedicated measuring instruments. Furthermore, to evaluate gear performance, functional assessments such as testing the actual meshing of the gears are also conducted. Through these quality control processes, it becomes possible to manufacture high-quality gears that meet customer requirements.

We are your reliable partner in gear injection molding.

What do you think? In this article, we introduced points to note in gear injection molding and the initiatives of Juraron Industries. If you are facing challenges with injection molding of small precision parts, please consider consulting Juraron Industries. With many years of experience and technical expertise, we support our customers in solving their challenges.

About JURARON Group

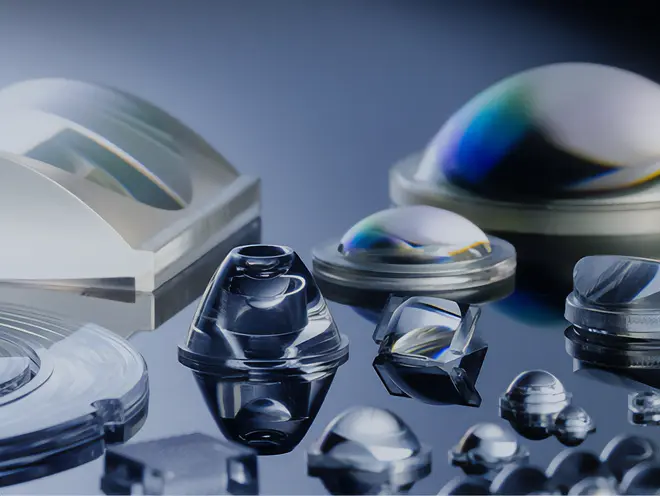

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.