Blogs

2025.11.30

Introduction to the characteristics of PC and key points of Injection molding

PC (polycarbonate) is a type of engineering plastic and a resin material with various characteristics.In this article, we introduce the characteristics of PC as well as points to note in injection molding.

We hope you find the information useful.

What is PC (polycarbonate)?

PC (polycarbonate) is an amorphous thermoplastic resin and an engineering plastic characterized by high transparency and excellent impact resistance.

Characteristics of PC (polycarbonate)

PC excels in heat resistance and dimensional stability, and is a self-extinguishing resin. Additionally, PC contains ester bonds, which are susceptible to chemical effects, and under high temperature and high humidity conditions, hydrolysis may occur.

Furthermore, PC is known to easily form composites with other plastics to enhance its characteristics and performance. By combining various properties, PC becomes a high-performance plastic material suitable for a wide range of applications.

Key considerations in PC (Polycarbonate) injection molding

Drying Conditions

In PC injection molding, the drying step to remove moisture from the raw material is critical. PC is a highly hygroscopic resin, and even a small amount of moisture can cause hydrolysis under the high temperatures of injection molding. As a result, defects such as silver streaks may occur on the molded parts, significantly reducing the material’s impact resistance and mechanical strength.

Mold Temperature Management

The mold temperature during PC injection molding is a critical factor that directly affects the dimensional accuracy, internal stress, and surface quality of the product. Since PC is an amorphous resin, if the mold temperature is too low, the molten resin cools rapidly inside the mold, generating high residual stress within the product. As a result, the impact resistance decreases, and defects such as cracks are more likely to occur.

Examples of PC products molded by our company

Component for OA Equipment

This is an example of molded parts for OA equipment using PC alloy material.

For this product, a strict dimensional tolerance of φ11.8 was specified. During molding, there was a concern that inward deformation could occur, causing the opening side to shrink due to thermal effects and potentially fall outside the tolerance range.

Therefore, during mold adjustment, the dimensions at both ends were adjusted to fall within tolerance, and core cooling was strengthened during mold trial to ensure dimensional accuracy.

>>For more details, click here.

Pulley for OA Equipment

This is an example of molded pulleys for OA equipment.

Because this product has a thick-wall structure and uses PC+GF material, maintaining dimensional stability of the circular sections was challenging, and sink marks during molding were a concern. Therefore, during the product design stage, we proposed a hollowing structure to achieve both appearance quality and dimensional stability.

In addition, the mold design included measures to minimize steps at the slide joint, and more gas vents than usual were provided to optimize the filling balance in the thick sections.

>>For more details, click here.

Leave PC (polycarbonate) injection molding to us.

How was it? In this article, we introduced the characteristics of PC and key points of injection molding. Juraron Industries Co., Ltd. has extensive experience in molding PC and can handle production of up to 5,000,000 units per month. Please feel free to contact us.

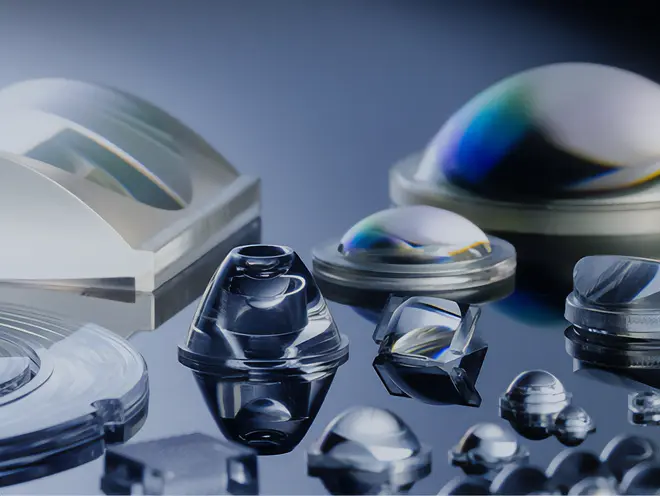

About JURARON Group

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.