Blogs

2025.11.30

Introduction to the characteristics of POM and key considerations in injection molding.

POM is a type of engineering plastic with a variety of distinctive properties. In this article, we introduce the key characteristics of POM and highlight important considerations for injection molding this material. We invite you to read further.

What is POM?

POM (polyacetal) is classified as a crystalline engineering plastic. It offers excellent wear resistance and high mechanical strength, making it suitable for applications subjected to load or repeated friction. Another notable feature of POM is its strong resistance to many organic solvents.

Thanks to these properties, POM is widely used in precision mechanical components such as gears, as well as various sliding and motion-related parts.

Key considerations in POM injection molding

Below, we introduce key considerations for injection molding POM.

Occurrence of jetting

In POM injection molding, if the gate diameter is too small, the resin flow speed increases as it passes through, causing the resin to solidify prematurely. As a result, streaks or lines may appear on the surface of the molded part.

To prevent this, it is necessary to raise the resin temperature to avoid premature solidification and reduce the injection speed at the gate to an appropriate level.

Occurrence of voids

In POM injection molding, voids may occur due to:

Shrinkage in thick sections (vacuum voids)

Gas formation or trapped air Voids can negatively affect the appearance and strength of the molded part, so appropriate countermeasures are necessary.

Specifically:

For voids caused by shrinkage (vacuum voids): consider modifying the product design (e.g., thinning thick sections) or applying rapid cooling after molding.

For voids caused by gas or trapped air: installing air vents in the mold and performing regular mold maintenance are effective measures.

Examples of POM injection molding at our company

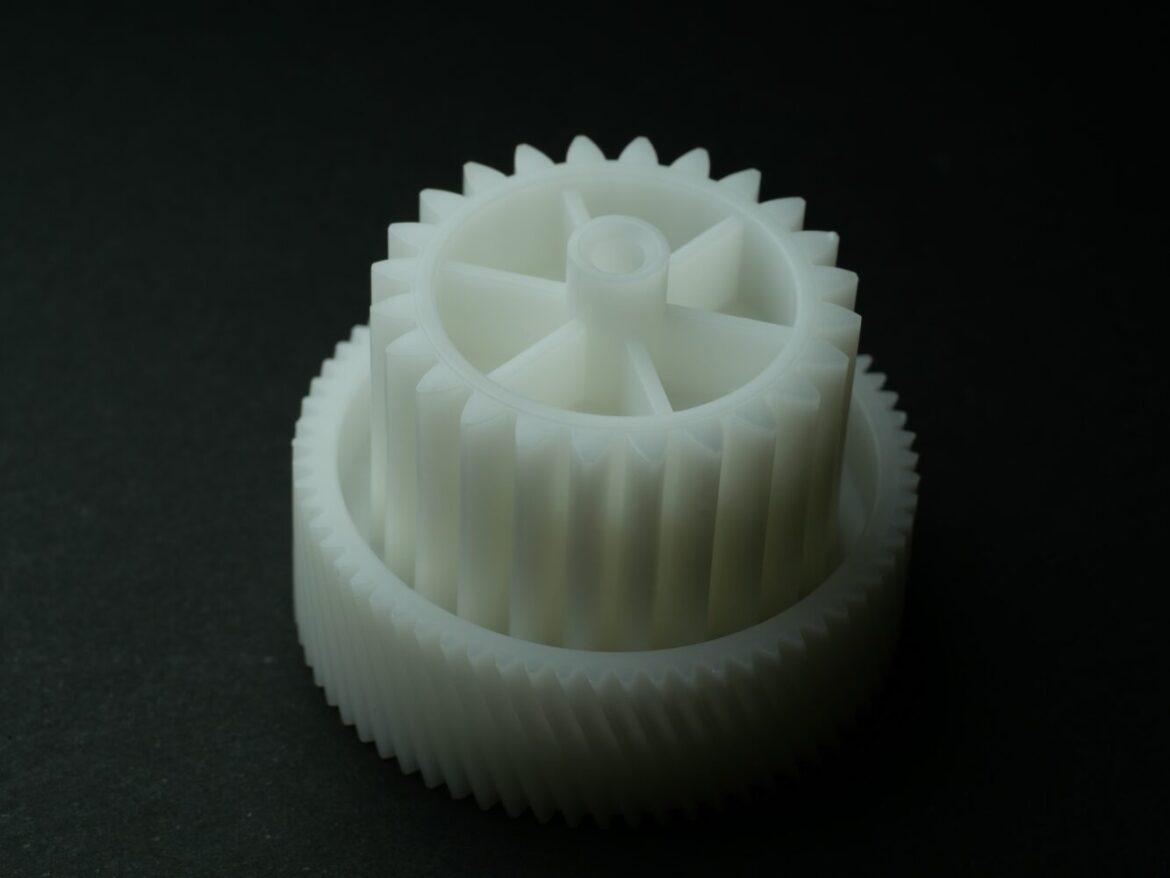

Gears for office equipment (OA)

This is a gear with an outer diameter of 36 mm and a height of 27 mm, manufactured using POM. Due to its shape, it is a part where maintaining dimensional tolerances is challenging. However, through optimization of processing conditions and special measures during molding, we achieved precision: total tooth surface meshing error of 112 μm and single-pitch meshing error of 26 μm.

On the other hand, some areas of this product are relatively thick, raising concerns about sink marks due to molding shrinkage. Therefore, material reduction were introduced to even out wall thickness, suppressing warpage and sink marks during molding, thereby preventing quality defects.

Light-blocking components for office equipment (OA)

This is a light-blocking component with an outer diameter of 31 mm and a height of 27.2 mm, manufactured using POM. It is used in office automation (OA) equipment to prevent external light from entering sensors that switch between black-and-white and color modes.

Some areas of this product are relatively thick, raising concerns about sink marks during molding. Therefore, we proposed a material reduction design to even out wall thickness, suppressing warpage and sink marks. Additionally, the addition of ribs increased rigidity, resulting in a structure that is resistant to deformation.

Trust us for high-quality POM injection molding

How did you find it? In this article, we introduced the characteristics of POM and key considerations for injection molding.

Juraron Industries Co., Ltd. has extensive experience in molding POM and can handle up to 10,000,000 parts per month.

Please feel free to contact us for consultation and support.

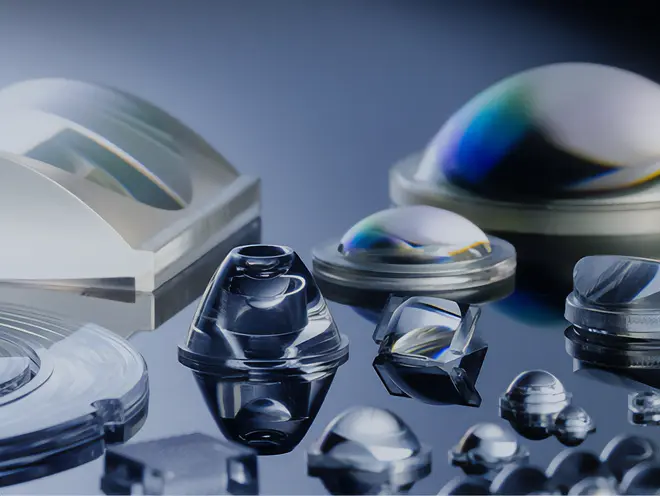

About JURARON Group

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.