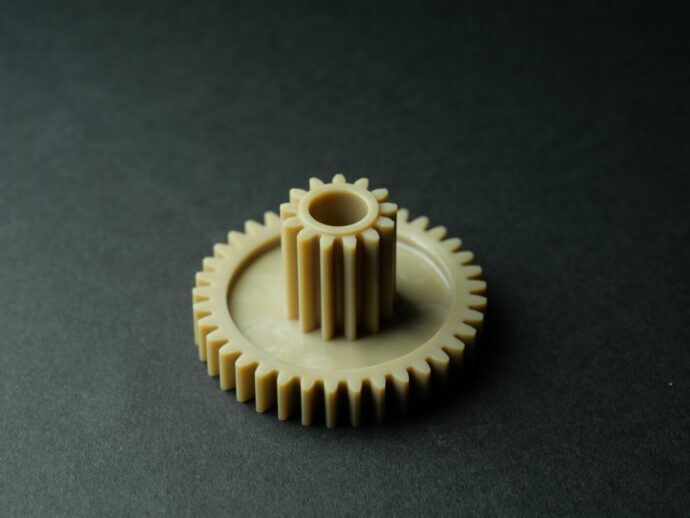

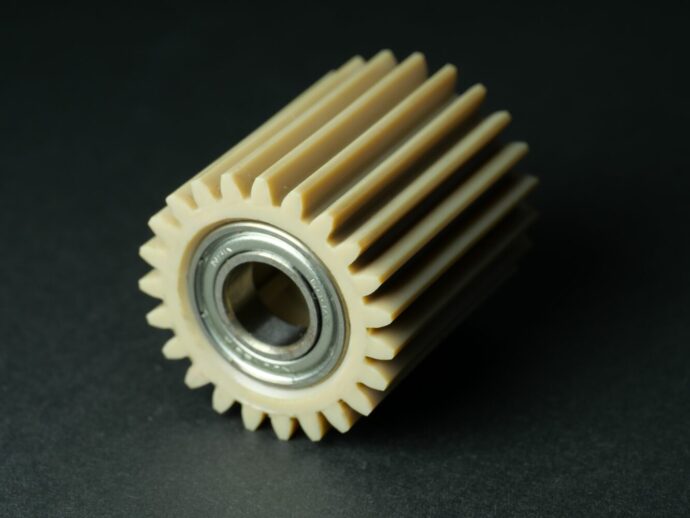

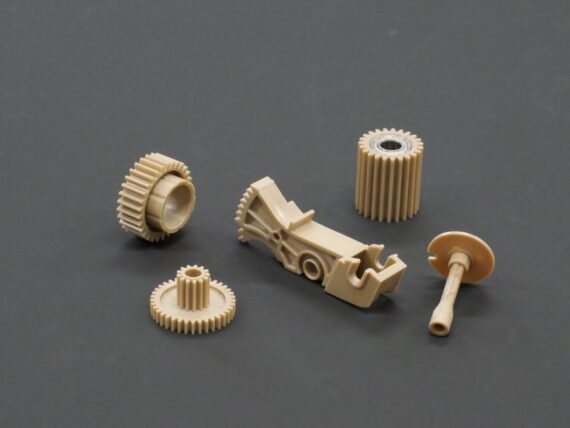

PEEK injection molding services

What is PEEK?

PEEK (Polyetheretherketone) is a high-performance engineering plastic known for its exceptionally high heat resistance, with a continuous service temperature of approximately 260°C, making it one of the top-tier thermoplastic materials. It also exhibits high mechanical strength and rigidity over a wide temperature range, along with excellent creep resistance and wear resistance. Another key characteristic of PEEK is its natural flame retardancy, with an extremely low risk of generating toxic gases.

Challenges in PEEK Injection Molding

High processing temperatures: PEEK requires a cylinder temperature close to 400°C and a mold temperature of approximately 180°C, making it one of the most demanding thermoplastics in terms of processing temperature.

Poor flowability: Due to its low fluidity, PEEK requires high injection pressure, and careful design considerations must be made for gate positioning and gas venting inserts.

Difficult mold release: PEEK has poor mold release properties, which can lead to issues such as parts sticking to the mold or remaining inside the cavity. Therefore, proper draft angles must be incorporated into the product design.

Challenges in molding precision gear components: Due to molding difficulties, achieving high precision in gear components is challenging. Experience in designing gate positions, ejection mechanisms, draft angles, and insert structures is essential for producing accurate parts.

Production Capacity

Production Capacity

Monthly Capacity:

up to 100,000 units

Equipment

high-temperature specification

Injection molding machines

Fanuc α-S15iA: 1 unit

Fanuc α-S30iA: 2 units

Fanuc α-S50iA: 2 units

Fanuc α-S100iA: 1 unit

FAQ

About Transactions

- Can we visit the factory?

- Where are your production facilities located?

- Can you handle production transfers?

- Do you have Japanese staff members?

- We are a company outside of Vietnam. Is it possible to have an online meeting?

- Can you support local companies in Vietnam as well?

- Is it possible to deliver outside of Vietnam?

- Which currencies do you support for transactions?

- What languages do you support?

About Molding

- What product sizes can you operate?

- Do you support drawings with inch specifications?

- Can you support assembly?

- Can you support prototyping?

- What materials can you operate?

- Is it possible to injection mold lenses?

- What post-molding processes can you operate?

- Can you operate product coloring?

- Do you handle hot runners?

- How long does it take until the first trial?

About Quality Control

About JURARON Group

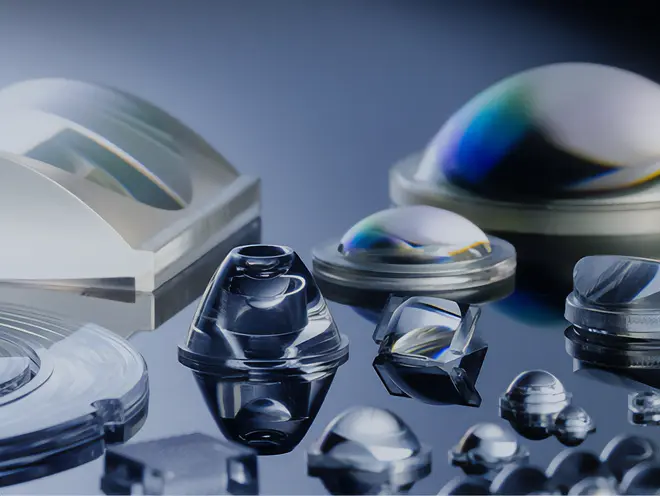

JURARON Group, with its headquarters in Japan, has expanded its branches in Vietnam, Hong Kong, and China. We specialize in the development, production, and sale of precision components,primarily made using injection molding technology. In addition, we provide optical design services, lens injection molding,and the production and processing of ultra-precision molds and components.

Please visit our website for more detailed information about our products and services.